Forged vs. Billet Lower Receivers

What should I choose, and Why?

Since its inception in 1956, and civilian accessibility in early 1964; the AR15 platform has become a favorite for hunters, sport shooters, and outdoorsman alike. Due to the modularity of the

AR15 platform; the aftermarket has exploded in recent years, and the consumer can now fully customize everything from stock to muzzle brake. When formulating a new AR build, I always find it best to start with the heart of the AR15: the lower receiver. Like all other parts that are available for the AR, the consumer has almost endless brands, styles, and prices to choose from when picking their lower receiver. However, there is one choice that the consumer MUST make before deciding on the previous lower receiver options: forged or billet.

A 20% Forged Receiver. This has been stamped, but not yet finished by a CNC

Forged Advantages:

A forged AR15 lower is essentially a block of high grade aluminum that is super heated, and then hammered into the shape of a lower receiver. The forging process hammers the molecules of the aluminum together, thus making it incredibly strong. In conjunction, forged lowers are typically lighter (though marginally) due to their design differences and tolerances when compared to billet lowers. Forged lowers are also easy to find, as well as the most commonly sold style of lower.

A finished (and anodized) 80% forged receiver.

Forged Disadvantages:

As with any product, there is give and take when choosing a forged lower. Perhaps the most important, is tolerance. During the forging process, aluminum is displaced when subjected to heat and pressure. This displaced aluminum often creates imperfections in the lower, and will need to be taken off. When taking off this excess aluminum, too much or too little may be taken off, causing imperfections in the fit and finish of the lower. These imperfections most commonly cause loose fitment when mated with the upper receiver, leaving gaps and spaces. The forging process also creates issues when the consumer wants a unique look to their rifle. Short of engraving; the forging process does not allow much possibility for unique styles, shapes, or designs that the consumer may want incorporated into his or her build.

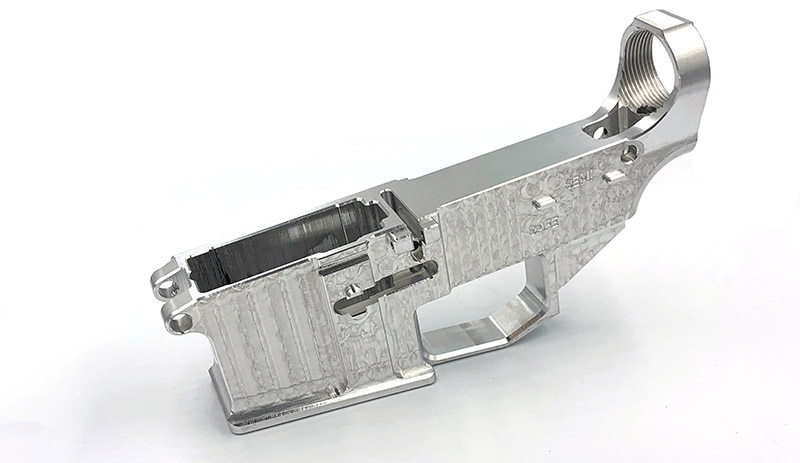

A Raw 80% Billet Lower. Many people choose an unfinished option and will paint or coat themselves once it's finished.

Billet Advantages:

A billet AR15 lower starts its life as a solid block of high grade aluminum, where it is then milled out by a CNC machine to form the final lower design. Due to the milling process, billet lowers are kept in extremely precise tolerances: typically measured microscopically to a millionth of an inch. When paired with a billet upper, the consumer can rest assured that the fit will be tight with no gaps between upper and lower. These tight tolerances aid tremendously in accuracy, while simultaneously making it harder for debris to enter the rifle. In addition, since the billet lower is stripped of material instead of pounded into shape, it is highly customizable. Customizing a billet lower is as simple as plugging in a design to the CNC machine. No shape, design, or style is off limits; giving your build that “one of a kind” completely custom look that will have your range buddies second guessing their builds.

An Anodized 80% Billet Lower Receiver. By far the most popular on the market, and winner of "Best 80% Lower" by PewPewTactical!

Billet Disadvantages:

Just like with forged lowers; billet lowers do have some draw backs. Billet lowers tend to be heavier due to the excess material left on for design or aesthetics, however the weight difference when compared to forged is minimal. Most consumers tend to agree that the custom look of the billet is worth the ounce or so of weight gain. Billet receivers are also typically more expensive; due to more material and labor needed to produce the lower when compared to forged--add on an additional cost if you have a completely custom design on your billet lower. Billet lowers are also technically not as “strong” as forged lowers, however unless you plan on testing your rifle to superhuman tolerances, neither the biller or forged lower will ever fail.

Aluminum 7075-T6 vs. 6061-T6

In terms of structural metal fabrication, aluminum is the only metal that can get closer to the attention received by steel. Albeit being a third of what steel weighs, aluminum has similar structural properties. Nevertheless, aluminum comes in an array of properties, and not all of them share the same features as steel.

6061 and 7075 are the two main common aluminum alloy grades that are used for structural applications. While they are similar in quite a several ways, there are still some differences that are worth taking note of.

The main difference between aluminum 7075-T6 and 6061-T6 is in the chemical composition and the alloy series. The 6061 will always have higher levels of zinc compared to the 7075. The next difference is in the chemical properties. A careful examination will reveal that 7075-T6 has higher tensile strength and is almost double that of 6061-T6.

Why Do Machined/Billet Lowers Cost More?

Compared to forged lowers, billet lowers usually cost more due to the manufacturing process employed and the quality or strength of the end product. Note that the machined lower commences with a billet block that is way larger than the end product.

Through shaving and cutting to achieve the desired specs, the block will be reduced in size. The remaining aluminum is either less or more wasted, based on the size of the starting block. While it will be sold at scrap, at the end of the day, you will end up wasting a lot of aluminum.

The machining process leverages an expensive CNC machine to achieve precision by moving the parts around. The cutting process and moving of the block require a lot of time compared to the simple forged process. This explains why machined/billet lowers costs more.

Why Are Machined/Billet Lowers So Popular?

There are many reasons why billet lowers tend to be quite popular. Whenever a structure is being selected, quality and durability come first. Since it is crucial to go for something highly durable and cost-effective, machined/billet lowers have achieved a lot of popularity.

6061, for instance, is excellently heat-treated, which lets it produce the greatest tensile possible, as well as yield strength. Higher yield strength is needed to let the alloy withstand more deformation and abuse without risking damage. If these are some of the things you are looking for, there is a good chance you will go for the billet/machined lower.

You will also get some critical advantages from its machining process. For instance, it is easily fabricated and designed and comes in an array of shapes accompanied by different features. The threaded fittings that they come with are also important features that make them unique.

Conclusion:

The “forged or billet” argument is one as old as time--or at least it feels that way. You will hear different parties swear by either one for a number of reasons, with each reason usually boiling down to personal preference. Sure the forged is technically stronger, and the billet is usually a little more expensive, but the forged is stronger in a “ Superman vs. Hulk” kind of way; and the billet is more expensive in a “why would I buy steel when the brass casings are only $.02 more” kind of way. It all boils down to personal preference, and how YOU the consumer wants your build to turn out, so check out our 80 percent lowers for sale today!

Back to List

Back to List